Interested in talking to us about one of our products?

Call us at (770) 684-2481 or email at sales@zauderer.com

Choosing the best plastic extrusion and polyurethane film is an important step in the manufacturing process. But with so many options, how can manufacturers know if they are choosing the right one? At Zauderer Associates, our sales team are professionals at helping manufacturers just like you find the best option, be it stock or custom.

Read on to learn about some of the most frequently asked questions when it comes to selecting the best plastic extrusions and polyurethane films for any job.

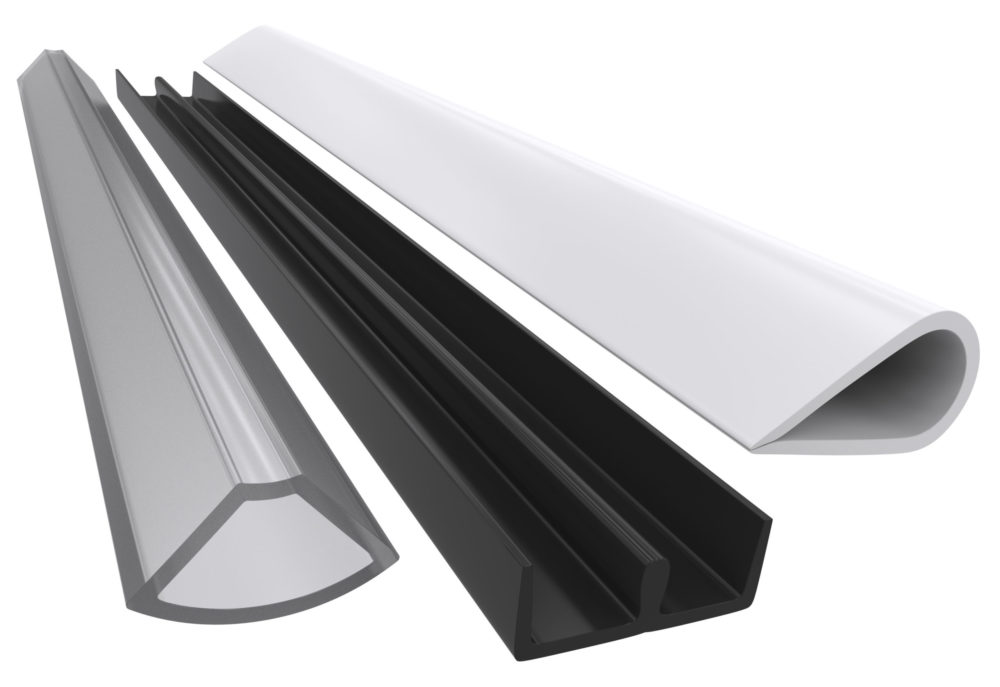

What are plastic extrusions? Plastic extrusions are created through a process by which plastic resin is melted, then extruded or pressed through a die, into one continuous piece. Plastic extrusions can be cut to almost any length and the profile can be formed or welded into a final shape. Plastic extrusions are a great choice because they are lightweight, provide excellent corrosion and cold resistance, and can be custom designed and integrated into the manufacturing process.

Both stock and custom plastic profiles and extrusions are available through Zauderer Associates. Instant quotes are available for a variety of stock profiles and extrusions. Items that are commonly in stock include:

If our stock extruded profiles and extrusions do not meet your needs for any reason, custom profiles to your print can be made to meet almost any requirement, including size, tolerances, raw materials, colors and secondary operations. Custom extrusions and channel prototypes are available for testing purposes, and fast quotes are available from our sales team.

Many different kinds of customizations are available for plastic profiles and extrusions. Common customization options include:

Zauderer Associates also offers engineering expertise to help modify or produce your designs to ensure your custom profiles and extrusions are exactly what you need.

Plastic profile and extrusions are used in many different industries and are preferred due to their customization options and relatively low price point. Common industries include:

What is polyurethane film? Polyurethane film is also known as TPU film, urethane film, or PU film. It is a flexible film that is frequently used due long term durability and strength. It has many unique characteristics, including resistance to abrasion, breathability, and waterproofing capabilities, among many other traits. Polyurethane film is used in many “Can’t Fail” applications. Our manufacturer has 60 extrusion lines total, including 30 vertical blown film lines and 30 horizontal sheet extrusion lines.

Polyurethane sheet extruded films are available in thicknesses between .010” to .060” and widths between 6” to 96”.

2,000 colors and 200 surface finishes are available, including matte, satin, semi-gloss, and gloss.

Yes, other films available include polyether urethane film, polyester urethane film, polyurethane barrier film, polyurethane breathable films, polyurethane blown film and hot melt film.

Yes, medical grade films are available. We supply many medical applications due to polyurethane film’s ability to act as a barrier film and a breathable film. Our medical grade films can also have anti-microbial and hypoallergenic additives. Our medical grade films meet the most stringent medical requirements and can be used for both internal and external applications.

Yes, Zauderer Associates can provide UV resistant film that is appropriate for outdoor application.

Polyurethane films are used in many different industries and are preferred due to their unique characteristics. Polyurethane films are used in many critical “Can’t Fail” applications in medical and defense products.

Common industries include:

Our experienced sales representatives can answer any questions you might have about plastic extrusions or polyurethane film and provide you with fast stock and custom quotes. Click “Request More Info” below to get started today.