Interested in talking to us about one of our products?

Call us at (770) 684-2481 or email at sales@zauderer.com

Choosing high-quality, reliable air moving components is essential for manufacturers. These components ensure the longevity, functionality, efficiency and overall reputation of your products among consumers. Explore this list of FAQs to guide you as you choose air moving components for use in your manufacturing operations.

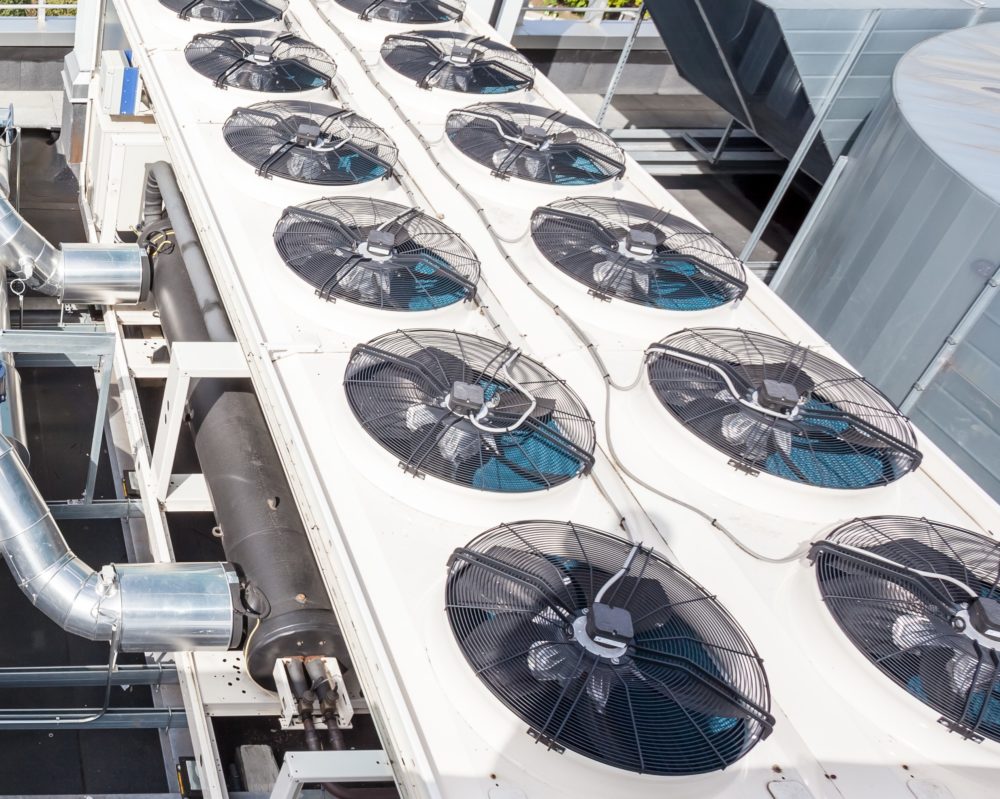

The type of product you are manufacturing, including its intended end-use, is the primary factor in determining what internal ventilation system needs to be installed. This also determines what types of components are needed when manufacturing these ventilation systems. Here are some questions you might consider when purchasing components for air moving packages like motorized axial fans, blowers, or welded wire HVAC motor mounts and fan guards.

Electronically Communicated (EC) fans are a more energy-efficient, powerful and flexible type of fan. EC fans are the latest trending technology, are maintenance free, and can reduce energy consumption in some cases by up to 35%. The EC motor’s integrated functions allow it to monitor temperature and load, and can adjust the speed of the fan depending on system factors.This allows for continuous control of pressure and/or airflow. Learn more about EC fans and motors.

It is important to know how many cubic feet per minute (CFM) you require in your air moving package and what components are needed. We have a very wide product range that will cover most or all of your requirements. For instance, our products range anywhere from 1 up to 30,000+ CFM, and static pressures range from free air up to 5 inches.

Underwriter Laboratories (UL) is one of the oldest product safety certifiers in the world. A UL Listed seal is proof the product has been tested for safety and sustainability standards. Not just fans, but every component of an air moving system, can be affirmed through checking for a UL listing or badge.

Fan guards support end user safety and are also important for OSHA compliance. The same is true of HVAC motor mounts that secure the motor. Here is what you need to consider when choosing hardware like fan guards or motor mounts.

There are multiple types of welds that might be used on the fan guard:

Each type of weld affects not only the cost of the fan guard but its reliability. All our fan guards are made with MIG welded intersections and can be fitted with sheet metal mounting points to withstand vibration-heavy environments. We have three state-of-the-art robotic welders to help facilitate any welding needs, which also reduces part costs. Our outdoor HVAC fan guards are powder coat painted in house for durability. We also have in house plating lines for electrodeposited zinc finishes.

Welded wire will resist environmental conditions that lead to rust as long as it is treated and finished in a quality fashion. This could mean galvanization, painting, coating, plating, or a combination.

Different fan guard finishes contribute to the quality and longevity of the product.

Our high quality industrial fan guards can be custom-designed, welded, and finished to meet exact client specifications along with OSHA guidelines.

Three-prong or four-prong motor mounts allow for small motors to be mounted for cooling towers, heat exchangers, refrigeration units, and more. We also provide fan guard/motor mount combinations that can support electric motors,hydraulic motors, and EC Motors.

Age and stress cause HVAC motor mounts to deteriorate over time. This stress could include vibration from nearby fans, or high temperatures.

When you replace an HVAC motor mount or blower motor in an existing ventilation system, this should reduce any vibration that was occurring because the old mounts allowed the motor to slip out of alignment. Make sure to choose a quality motor mount to equip the blower motor to withstand the impacts of vibration from any nearby fans and machinery. Fan blades that are out of balance are normally the source of any vibration and should be inspected and/or replaced.

The axial fan is the oldest design of a fan and is used in many applications for heating, cooling, or ventilation. What is important in manufacturing is energy efficiency and ensuring consistent performance as the CFMs moving through the ventilation system go up or down.

Axial fans can use AC, DC, or EC motors. The type of fan you need depends on the voltage value available and whether that is fixed or can fluctuate. With each application you also need to determine what your static pressure is and what type of CFM is needed. Static pressures go up if you are pushing air through a filter and/or condenser or evaporator coil. As the filter and coil clog up your static pressures will also go up. You need to take this into consideration when designing your air moving packages. Additionally, different fan blades have different functionality. We can adjust the pitch of our fan pedals at one-degree intervals. Normal pitches are in the range of 20-55 degrees. Contact us if you need help deciding which type of fan is best for your air moving packages.

One piece axial fan propellers are ideal for low-stress situations. One piece fan blades are produced from 3” diameter to 14” diameter. Riveted propellers can stand up to higher speeds and static pressures and are available from 10” diameter to 60” diameter.

Whether one piece or riveted, industrial fan blades can be made of many materials, including:

These materials are often determined based on the client’s unique needs, and custom materials can also be used.

Finishes for industrial fan blades help the fans resist high temperatures and rust/corrosion. These finishes include:

As with fan blade materials, finishes can also be customized.

Whether a minimum quantity of fan blades needs to be purchased depends on the material, finish, size, and shape of the blade. If the industrial fan blade is commonly in stock, we sell individual blades or smaller batches. If a blade must be custom created, a larger purchase would be advisable simply for the manufacturer to make operations more efficient.

We hope this list of FAQs has given you some insights into choosing air moving components and other essentials like HVAC fan guards and HVAC motor mounts for your manufacturing operations. If you still have more questions about your needs or whether we have the hardware in inventory to fill your industrial ventilation order quickly, reach out to Zauderer Associates today.