Zauderer Associates has partnered with an expanded metal manufacturer for over 25 years. We are very knowledgeable in this industry and have long standing relationships with many customers.

The products produced are of high quality and are able to meet very demanding specifications. Our partner has all types of equipment enabling you to achieve your product needs. Equipment includes expanders, flatteners, slitters, die cutting tables, presses, roll formers, shear tables, extruders, unwinders, rewinders and upenders.

Some Of The Industries We Serve:

Aerospace, Agriculture, Construction, HVAC & Air Filtration, Medical

Learn More About Our Products

The Importance of HEPA Filters and Expanded Metal in the Clean Air Industry

HEPA filters are a key component to preventing the spread of airborne bacteria and viruses. To be categorized as a HEPA filter, high efficiency standards must be met.

Distributors vs. Manufacturers of Expanded Metal

Here are some of the highlights and unique characteristics of an expanded metal manufacturer in contrast to an expanded metal distributor.

How is Expanded Metal Made?

Click to learn more about how expanded metal is made and to watch a video

Expanded Metal Sizing Guide

In order to understand how to decide the correct expanded metal pattern and size for your project, it is important to understand what expanded metal is and basic expanded metal terminology.

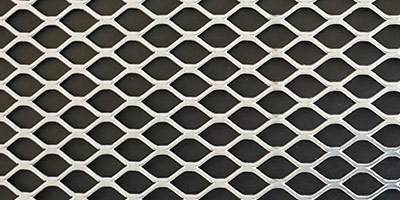

Expanded Metal

What is expanded metal / expanded metal mesh?

Expanded metal / expanded meta mesh is made by an industrial die that cuts the metal while simultaneously being expanded to create a diamond pattern. The result is a sheet of expanded metal that is lighter and less expensive than the original solid metal sheet; however, strength and rigidity is still maintained. Expanded metal can be either flattened or unflattened. Flattened expanded metal simply has a secondary operation applied to it where it is cold-rolled through a flattener and the result is a smooth and flat sheet of expanded metal. Unflattened expanded metal has no secondary operation performed to it and therefore has a louvered appearance.

How is expanded metal made?

Expanded metal is made by placing a single sheet of metal is put into an expanding machine that also has an oscillating knife that can cut in different dimensions. As the metal goes through the machine, it is cut and then also stretched to make the holes.

While the basic manufacturing of expanded metal is relatively simple, determining the exact size, type, pattern, materials, finishes required to fit your unique needs is where we can help. Zauderer Associates, Inc. has years of expertise to make sure the expanded metal mesh that your product requires is manufactured correctly.

Do you make expanded metal in coils?

Yes, expanded metal can either be cut to length (produced to a specific width and length) or be purchased in coils (produced to a specific width and then wound onto a core). Coils are typically purchased at 2,000 feet or more.

What sizes does expanded metal come in?

Expanded metal comes in a variety of sizes and patterns. To determine the correct expanded metal for your application, various requirements need to be considered including the required strength, type of metal needed and how much airflow is required. The thicker and wider the stands of expanded metal are, then the stronger the expanded metal mesh will be. The starting raw metal thickness determines how thick or thin the expanded metal will be. If more airflow is needed, then larger openings need to be created into the expanded metal. Our capabilities for sizes includes a width range from 2” to 48” and thickness from .0016” to .032” for steel and 0.016” – 0.055” for aluminum.

Can you customize the expanded metal sizes?

Yes – we specialize in creating custom component parts and assemblies and can customize expanded metal size. We can work with you to determine exactly how thick, wide, and long you need your expanded metal mesh to be. We can meet even the most demanding specifications.

How strong is expanded metal?

One of the primary reasons that expanded metal is chosen for numerous products, is the fact that it is lightweight but still extremely strong. Expanded metal maintains its strength since the openings are cut out of the original sheet metal and there are no pieces of material welded together.

Does expanded metal rust?

It depends on what type of materials and finishes are chosen whether there is any rust protection or not. CRS (cold rolled steel) expanded metal will rust just like any other steel product. Below is a list of common materials and information on rust protection:

- CRS Steel – usually powder painted, no rust protection.

- G30, G60, or G90 Steel – hot dipped galvanized coatings, good rust protection

- Electro Galvanized Steel – electro galvanized process, good rust protection

- Aluminized Steel – high temperature protection, good rust protection

- Aluminum – good rust protection

- Copper – usually for decorative applications

What materials can you make expanded metal out of?

Expanded metal can be made from many materials, including:

- CRS Steel – usually powder painted, no rust protection

- G30, G60, or G90 Steel – hot dipped galvanized coatings, good rust protection

- Electro Galvanized (EG) Steel – electro galvanized process, good rust protection

- Aluminized Steel – high temperature protection, good rust protection

- Aluminum – good rust protection

- Copper – usually for decorative applications

How to order expanded metal?

Reach out to Zauderer Associates, Inc. today to discuss the customized expanded metal product that you need. We have been helping manufacturers simplify the purchasing process of expanded metals for over 40 years. We can help you navigate expanded metal pricing, size and strength considerations and finishing options that will meet your exact specifications.

What are the primary features of expanded metal?

Expanded metal is often the material of choice to do its broad features:

- Cost effective since very little scrap is produced.

- Very durable and extremely strong. It can add structural strength to the product using it.

- Various protective finishes and colors can be chosen based on the product requirements.

- Lightweight but still provides strength and resistance.

- Can provide adequate ventilation, airflow, and lighting if required

- Economical / less expensive alternative to sheet metal.

- Anti-slip properties due to the cut-out diamond holes

What is expanded metal used for?

Due to the many advantages of expanded metal, there is almost an endless amount of uses and industries where expanded metal can be found. Furniture / benches often are made of expanded metal due to its durability and strength. Products needing filtration or ventilation capabilities will look to expanded metal since it provides excellent airflow. Expanded metal can even be grilled and cooked on and is used for some decorative products like firepit covers or fireplace screens.

Other products where you can find expanded metal include automotive air filters, heavy-duty air filters, HVAC filters, HEPA filters, appliances, electrostatic home furnace filters, security door and window screens, office partitions, ceiling registers, chimney caps, gutter guards, fireplace screens and battery mesh.