Interested in talking to us about one of our products?

Call us at (770) 684-2481 or email at sales@zauderer.com

In order to understand how to decide the correct expanded metal pattern and size for your project, it is important to understand what expanded metal is and basic expanded metal terminology.

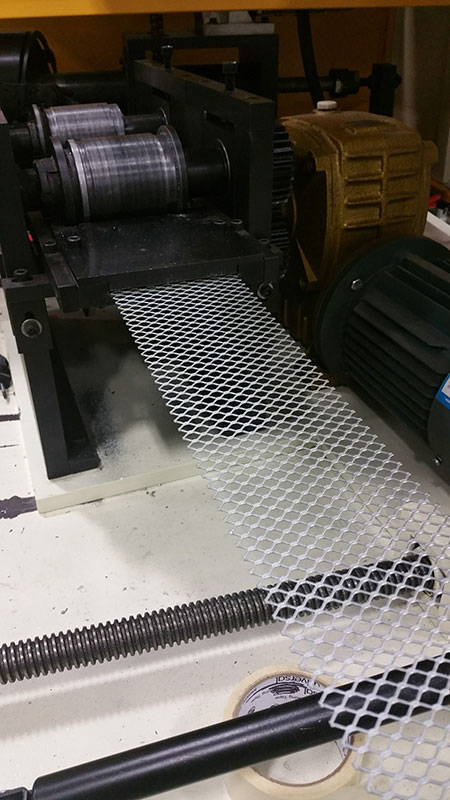

Expanded metal is a rigid and semi rigid, strong piece of metal that is first sheared by an oscillating knife while simultaneously being expanded into an open mesh pattern. The result is a sheet that is lighter and less expensive than the original solid metal sheet, while still maintaining strength and rigidity.

Expanded metal can also be purchased cut to length (produced to a specific width and length) or in coils (produced to a specific width and then wound onto a core). Coils are typically purchased at 2,000 feet or more.

Expanded metal can be either flattened or un-flattened. Flattened expanded metal is cold-rolled through a flattener, after expansion and produces a smooth and flat sheet. Unflattened expanded metal has no secondary operation performed on it and therefore has a louvered appearance.

See diagram for additional clarification on Expanded Metal Terminology.

When determining the correct expanded metal for an application, various requirements of the project need to be considered including the required strength, the type of metal needed, and how much airflow is required. The thicker and wider the strands of expanded metal are, then the stronger the expanded metal will be. The starting raw metal thickness will determine how thick or thin strands can be. The expanded metal tool, typically called a knife, will determine how large the openings are able to be. Lastly, larger openings will create more airflow. All these variations need to be considered in conjunction with your specific project. Once this is determined, then recommendations can be made for the right material, thickness, and opening size.

Please click “Request More Info” below to discuss your expanded metal needs.

To learn more about how expanded metal is made and to watch a video, click here.