Zauderer Associates has years of experience working with Springs & Wire Forms. We will assist you throughout the purchasing process to ensure that you get the exact product that is needed.

The manufacturers that we partner with focuses on providing excellent customer service and high quality products. No matter what type of Spring or Wire Form you may need, your project will be a success due to the innovative solutions and support you will receive through the process.

Some Of The Industries We Serve:

Appliance, Furniture

Springs & Wire Forms

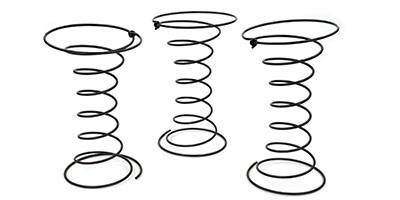

Furniture Springs

What kind of springs are best for upholstered furniture?

There are two primary types of springs found in upholstered furniture: coil springs and zig zag or sinuous springs. Sinuous springs or zig zag springs are made from one pieces of metal and are bent into a zig zag. The material typically used in sinuous springs are in gauges 8 to 11 GA wire. Custom radius is an option and sinuous springs are typically manufactured in cut-to length pieces. Coil springs are individual springs that can either be formed as open coils, as soft edge or lip coils, or with one end knotted (K1E or K0E). Coil springs are formed with high-carbon spring wire and heat tempered to ensure resilience. Furniture manufacturers can determine the desired coil gauge and height.

What is better than 8-way hand tied?

Rigid bar drop-in construction units are an excellent alternative to 8-way hand tied furniture. The rigid bar drop-in construction unit that we sell is the best in the industry. It strengthens the customer’s frame, allowing them to remove wood slats or bracing and it can be installed by anyone, typically with 6 to 8 screws. The units can be modular (one for a chair, two for a loveseat, or three for a sofa), which allows the customer to cut down on SKUs and eliminate freight and handling issues with large one-piece sofa drop-ins. These rigid bar drop-in units greatly increase throughput in the plant due to the ease of installation and these units can match or better the ride of an 8 way-hand tied piece of furniture.

Can your furniture springs be customized?

Absolutely. Providing custom component parts is what we do best. We can assist in customizing various options including the wire gauge, height, and size of the springs to deliver the desired level of firmness or softness to your unique furniture design.

What is a Marshall Spring?

A Marshall spring cushion unit consists of coil springs that are encased in durable material and either scrim-glued or hog-rung to create the desired comfort and ride. The springs are pre-tensioned to the correct height and can be customized.

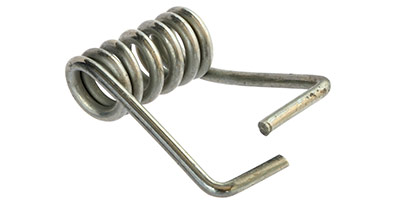

Mechanical Springs

What types of mechanical springs are available?

Recoil/constant force, compression, extension and torsion springs are available.

What makes your mechanical springs unique?

The mechanical springs that we can provide will work consistently and will not breakdown prematurely. They can be made with coilers, a CNC Spring Forming Machine and hand forming. The extensive experience in manufacturing mechanical springs shows through the high quality springs that are designed and delivered.

Wire Forms

What materials are available for wire forms?

Carbon steel, brass, copper, stainless steel are often used; however, other metals are also available.

What additional capabilities are available for wire forms?

Ball ends, deburr, multi-dimensional forms, springback and tensile requirements.

Can you customize wire forms?

Absolutely. Our manufacturer has multi-slide machines, verti-slide machines, CNC forming machines that allow for the manufacturing of complex wire forms. There is a prototyping department that can work with you to make sure that the project is a success and that the exact specifications required are produced consistently. Our wire forms can be found in a large assortment of finished products including dishwasher baskets, automobile, kitchen utensils and residential yard stakes.