Interested in talking to us about one of our products?

Call us at (770) 684-2481 or email at sales@zauderer.com

It might be! Proof loading/testing is a quality control measure used to prove out a design and/or is required for annual inspections, to meet certain safety and mandated, governmental regulations. Is your wire rope cable used in an industry where there is higher risk of danger to personnel, damage to equipment or failure of critical function? Will the failure of your wire rope cable assembly cause bodily injury to your employees or to operators of your finished product? Are you required to certify your design? Is your product containing wire rope cable intended to give years of rugged use or to be used once without failure? Does your wire rope cable see a shock load or a bending moment regularly?

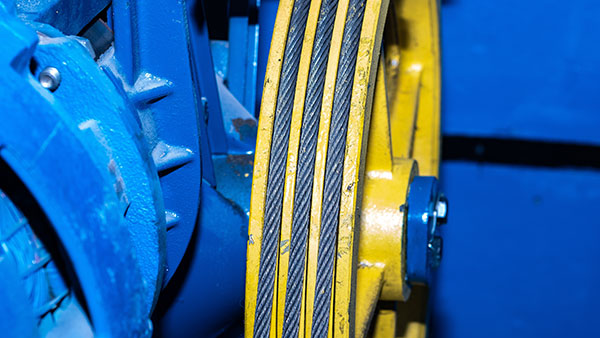

Some examples of where this testing could or should be used includes military applications, aircraft, space craft, elevators, cranes, patient lifts, cradles, web slings, lifting accessories, construction, employee protection devices, winches, hoists, and many more areas of everyday life.

So, what does it mean to proof load wire rope cable? Proof loading is the application of a prescribed nondestructive static tensile load to your cable assembly to certify the design criteria. Proof loading will ensure that the construction and workmanship of your product meets or exceeds the load your product will see in normal use, with an additional safety factor built in. It will ensure that the wire rope cable, plus the fittings used and attached, will not deform, or fail. This means your cable assembly will perform as intended, under the working load limit (WLL) or a multiple thereof.

Proof loading or prestressing can be done as a quality inspection for each time a production run is made or can be done to each cable to ensure no failures. Prestressing is a load that is applied to the cable, at 60% of its rated break strength to remove constructional stretch. This ensures that minimal adjustments will be needed to maintain proper tension in a control system. All the slack is taken out of your “system” and it is ready to function the way you intended.

In summary, under a proof load or prestress, your cable assembly will be tested in a static tensile strength tester and pulled to a prescribed load. Then your parts will be visually inspected for physical deformation. The strength of wire rope, the working load, and the safety factor of wire rope cable so that your assembly and design work safely and as intended.

Bring us your wire rope cable design, your criteria, your application and let us put our years of experience to work for you, to come up with a cost-effective design that meets your needs. Let our team go to work for you.

Would you like to learn more about Wire Rope Cable? Click here for additional topics and to learn about various type of products and assemblies offered.