Interested in talking to us about one of our products?

Call us at (770) 684-2481 or email at sales@zauderer.com

HEPA filters are a key component to preventing the spread of airborne bacteria and viruses. To be categorized as a HEPA filter, high efficiency standards must be met. And to manufacture a HEPA filter, expanded metal is often a necessary material. Below are frequently asked questions about HEPA Filters and expanded metal:

A HEPA filter stands for a “high efficiency particulate air” filter. Common standards in the United States provide that HEPA filters must remove 99.97% of particles whose diameter is equal to 0.3 microns when air passes through it. For comparison, a human hair is somewhere between 50-70 microns so the particles that a HEPA filter can pick up is extremely small.

A finished HEPA filter are all constructed slightly differently based on the final application; however, most all HEPA filters include the filter media, aluminum extrusions (frame), adhesives, seals, and expanded metal (media protection).

Expanded metal is the outside screen that protects the filter media while allowing air to pass through the filter at a predetermined air flow rate.

The expanded metal pattern for HEPA filters is typically .250” SWD x .500” LWD allowing for a 72% – 75% air flow rate. The expanded metal is cut to the exact size of each HEPA Filter and is then powder coated white to an industry standard used internationally.

There are many applications for HEPA filters including:

Because of a HEPA filters ability to trap harmful particulates, these air filters, especially medical grade HEPA air filters, are very important in the fight against COVID. There are many companies that manufacture HEPA Filters for clean room industry applications as well as hospitals, however, there are a select number of companies that have been designated by the CDC, FEMA, and the Department of Education to fight the viral load of Covid and other airborne particulates. We supply to all these companies.

There are no disadvantages other than price, as HEPA Filters are more expensive than normal air filters. The advantage of a HEPA Filter is its ability to strip out of the air, almost all harmful particulates caused by airborne disease, chemical contaminates, smoke, pollen, and air pollution.

Air purifiers are not harmful unless they perform at a sub-standard level due to design or manufacturing defects. HEPA filters are fragile and can be damaged in transit or upon installation. Due to the critical, cannot fail, type applications where HEPA filters are often used, it is important that HEPA filters be tested and checked frequently to be sure they are operating as expected.

With an H14 HEPA filter, the volume of air that fits through the filter is smaller than with an H13 HEPA filter due to the filter density. Also, if the air flows through the filter only once, it will be cleaner with the H14 filter than with an H12 filter.

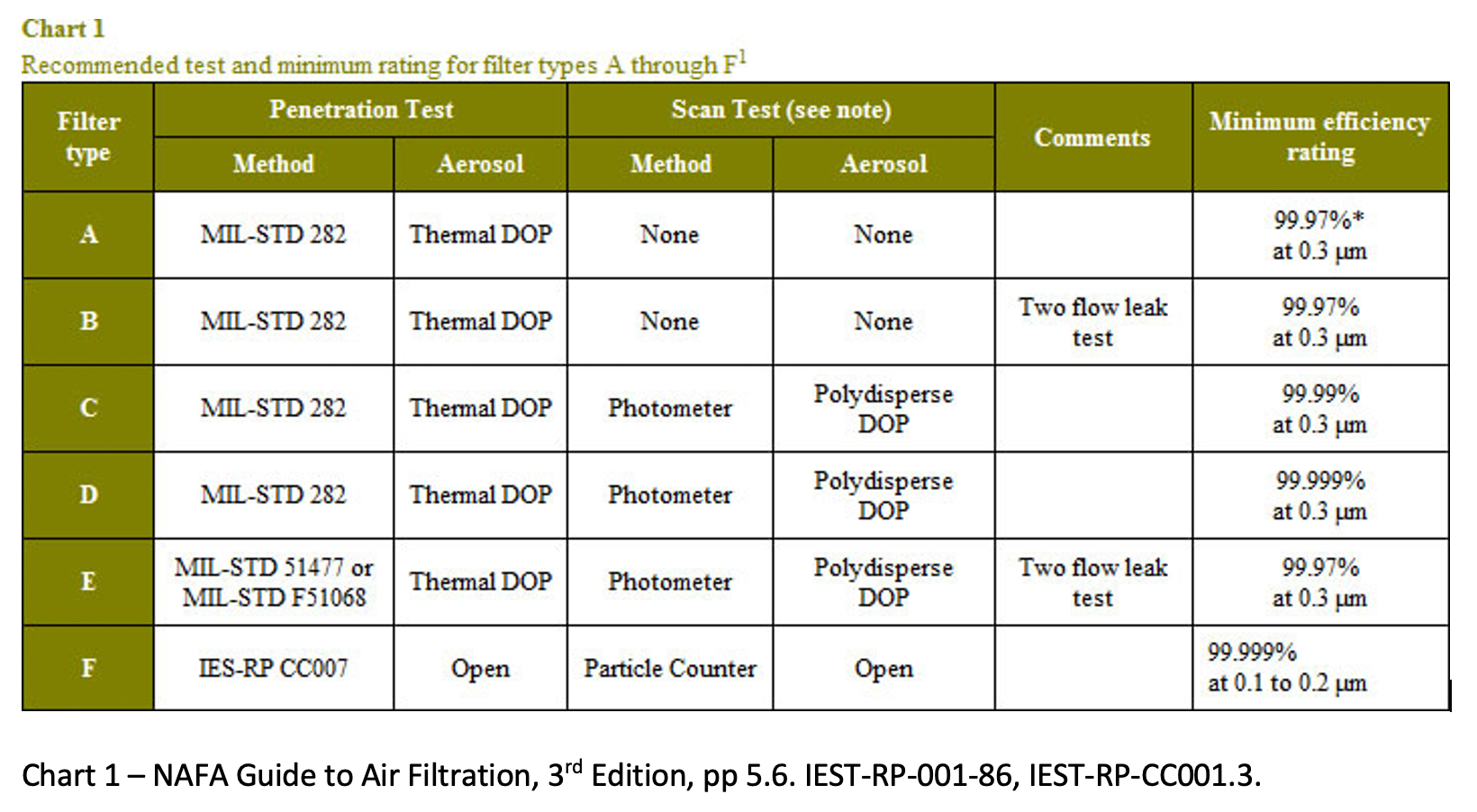

Since a “HEPA Filter” is technically a standard of efficiency and a type of technology, there can be many different types of HEPA Filters. The layering of materials that are used, the sizes of the finished filter, the application where the filter is used all result in different “HEPA Filter types.” However, when looking specifically at the performance of a HEPA filter, there are 6 primary types according to the Institute of Environmental Scient and Technology (IEST). The types are categorized as A, B, C, D, E & F and each have distinct characteristics outlined below: