There is almost an endless number of wire rope applications that all have different strength and flexibility requirements. In order to determine your unique wire rope requirements, it is important to understand the basic configurations and characteristics of wire rope cable that determine its overall strength. Three primary areas that determine the strength of wire rope cable include:

- Wire configuration

- Cable diameter

- Wire material and coatings

Wire Configuration:

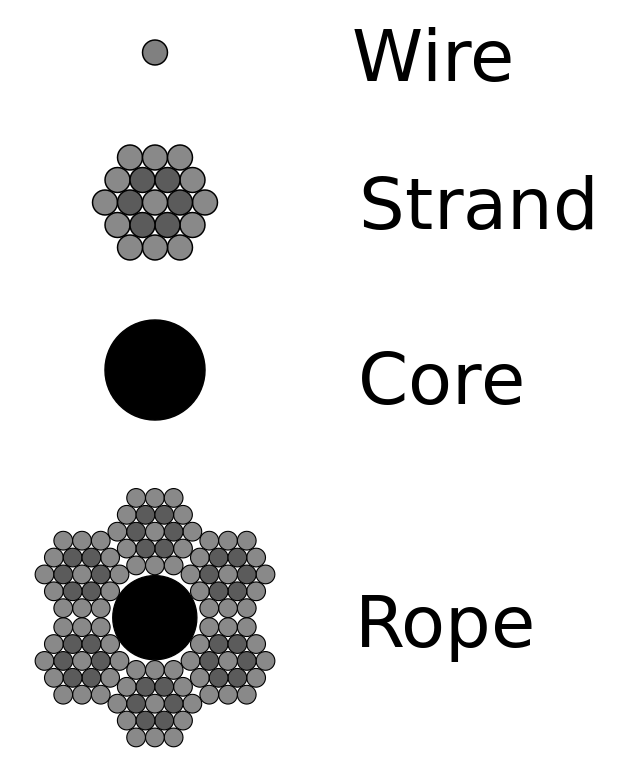

As shown below, there are 3 basic parts to wire rope: the wire, the strand and the core all combine to form the wire rope. There is a standard naming convention of wire rope, which is the main component that will determine the strength of wire rope:

(Number of Strands) X (Number of Wires per Strand)

For example, a 7 X 19 wire rope is comprised of 133 total wires. There are 7 strands in total and 19 separate wires make up each strand.

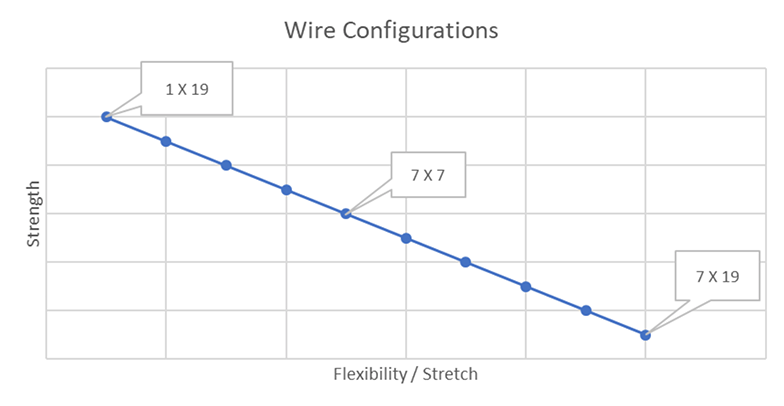

There is an inverse relationship between the strength of the wire rope and the flexibility / stretch of the rope as more strands and more wires per strand are added. As shown below, 1 X 19 is the least flexible but has a high breaking strength. 7 X 7 is more flexible and has medium strength and 7 X 19 is the most flexible but has the lowest breaking strength.

There are numerous configurations of miniature wire cables that we can supply based on your unique requirements. Below are some of the most common wire strand configurations:

- 1 X 7 = 7 wires

- 1 X 19 = 19 wires

- 3 X 7 = 21 wires

- 7 X 7 = 49 wires

- 7 X 19 = 133 wires

- 7 X 49 = 343 wires

Cable Diameter:

The diameter of each individual wire, in conjunction with the wire configuration will determine the overall wire rope cable diameter. As the diameter increases, the breaking strength of the wire will also increase. It is recommended to select a cable with a minimum breaking strength of 10 times the actual load requirement that you need for your project.

Wire Material and Coatings:

There is a large assortment of materials that are used to make wire rope that will all determine the overall strength of the wire. Some of the materials we offer include Stainless Steel, Galvanized Steel, Tungsten, Nitinol, Vitallium, Inconel, Titanium, and Molybdenum. Each material not only has different purposes and applications but will also determine the overall strength of the rope.

Additionally, wire rope can be either coated or uncoated. We have a variety of coatings that also provide different flexibility and strength. We offer nylon, vinyl, FEP, polypropylene and polyethylene extruded coatings.

There are many considerations that go into determining the overall strength of wire rope and your project has a unique set of requirements. We look forward to working with you to determine exactly what type of wire rope fits your needs.

Please click the “Request More Info” button below to learn more and to discuss your specific needs.