Interested in talking to us about one of our products?

Call us at (770) 684-2481 or email at sales@zauderer.com

Zauderer Associates has in depth knowledge and years of experience with aluminum extrusions, plastic extrusions and metal stampings. We help to provide all engineering support and design assistance for your projects, no matter how simple or complicated.

Our partners have a large selection of parts and the ability and tools to create custom parts as needed. The quality of all parts are excellent and customer satisfaction is the priority. Our partners offer full-service capabilities so your entire project can be completed with one order from design and engineering assistance to extruding / stamping to finishing and packaging.

There are many benefits of aluminum extrusions including that they tend to be less expensive than casting molds, have a very smooth finishing surface, highly adaptable and customizable for a variety of shapes, and are very strong but still lightweight.

We offer many options of both painted or anodized finishes to complete your standard or customized aluminum extrusion:

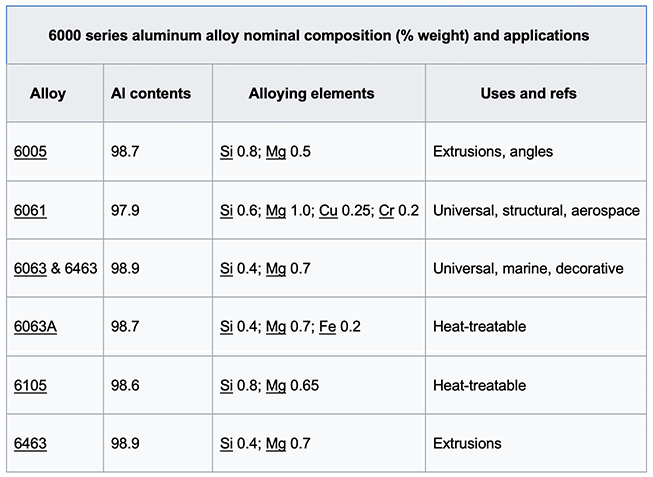

Determining the correct alloys to use in an aluminum extrusion is very important as it can alter the strength, durability, corrosion resistance, and appearance of the finished aluminum extrusion.

6000 series are alloyed with magnesium and silicon. They are easy to machine, are weldable, and can be precipitation hardened, but not to the high strengths that 2000 and 7000 can reach. 6061 alloy is one of the most used general-purpose aluminum alloys. Below is a list of alloys available:

The shape of the aluminum extrusion determines the exact size that can be fabricated; however, a general range is from ½ inch up to 25 feet.

Yes, the extruder can provide mill, anodized and painted finishes on the custom and standard aluminum extrusions.

There are many fabrication services available including complex bending, Mig & Tig welding, precise hold punching, milling & nothing, drilling & tapping, mechanical & welded assemblies and all types of mechanical finishes.

The cost of an extrusion die varies greatly based upon the complexity. Our manufacturer has access to have 2,500 standard shapes available, so it is possible that we already have the die ready to go. However, we offer the ability to create customized shapes. The cost of a customized extrusion die will depend on the size and intricacy of the extrusion product.

There are many steps in the production cycle of an aluminum extrusion. First, you must work with the design team and engineers to create the right cross section needed for your product. The extrusion die is then created or prepared to move through the extrusion press. An aluminum billet, which is what determines the size of the aluminum extrusion, is preheated and transferred to the extrusion press. A ram pushing the billet material into the container where the extrusion press is, and the extruded material emerges through the die. The extrusion is cooled and then cut to the correct length. Next the aluminum extrusion can get various finishes for appearance purposes and/or protection against environmental factors and corrosion.

There are many steps in creating a customized aluminum extrusion and Zauderer Associates, Inc. can assist you throughout the entire aluminum extrusion production process including the design and engineering, extruding, finishing, fabricating and can help ensure timely delivery.

Roll forming is the perfect manufacturing process when many of the same shape product is needed. It is also great for products with long profiles including fencing, door and window hardware and drawer slides. Roll forming products have tight tolerances and high-quality finishes. Roll forming is a great manufacturing process when custom components are needed.

Roll forming is the process of incrementally bending strips of metal through using a placement of precise rollers through a roll forming machine. A roll forming machine will have multiple stands and in each stage the material will be progressively shaped. After the shape is created there are a variety of secondary operations that can be performed to the metal including bending, embossing, flattening, hand welding, in-line punching, mitering, notching, piercing, punching, stamping, tabbing, tapping, and minor assembly. Additionally, there are a variety of finishes available including anodized, chrome plated, polished, powder coated, pre-coated, pre-finished, pre-painted, pre-plated and zinc plated.

Benefits of roll forming include cost savings especially when producing large quantities, ability to customize and shape products regardless of metal and type of finish, consistent product, and limited scrap.

Roll forming is a manufacturing process that can use virtually any metal and their alloys, including materials that already have finishes on them. Materials available include aluminum, brass, bronze, carbon steel, copper, stainless steel, steel, cold rolled steel, galvanized steel, high strength steel, hot rolled steel, tin plated steel and vinyl clad metals.

Thickness of roll formed parts can range from 0.018 inch to 0.1644 inch – up to 8 gauge material thicknesses.

Very long parts, up to 45 feet long can be roll formed. Additionally, very small parts around 12” can also be roll formed.

After the shape is created there are a variety of secondary operations that can be performed to the metal including bending, embossing, flattening, hand welding, in-line punching, mitering, notching, piercing, punching, stamping, tabbing, tapping, and minor assembly. Additionally, there are a variety of finishes available including anodized, chrome plated, polished, powder coated, pre-coated, pre-finished, pre-painted, pre-plated and zinc plated.

This varies by the complexity of the shape and number of bends to achieve the final design. Cost for tooling is dependent on how many stations will be needed to bring the flat starting metal coil into a final shape and design. Increase the number of stations and the cost increases. In general, a roll forming tool can run between $15,000 – $100,000. In most cases, roll forming is best suited for high volume applications due to the upfront tooling costs.

There are generally thought to be four types of stamping methods. The chosen method is dependent upon the outcome desired and specified by the engineer:

There are three main types of metal stamping presses:

Metal stamping dies generally fall into two primary groups:

Due to the versatility of metal stamping, these products can be found in various industries and products including automotive, aerospace, agriculture, appliances, construction, furniture, electronics, and transportation.

Metal pressing and metal stamping are essentially interchangeable terms for a very similar manufacturing process.

One of the biggest advantages of metal stamping is that it has a high degree of accuracy. Complex and customized designs can be created rather easily with a die and can be repeated with precision. It is also an inexpensive manufacturing method especially when manufacturing large quantities.

The metal gauge that is best for metal stamping depends on the type of press used. Thin metals in the .005” range or lower can be stamped on low tonnage, high speed presses such as Bruderer Presses. Thicker gauge metals can be stamped on larger 50 ton – 750 ton presses.

A flat piece of metal is transformed into a desired shape by using a die. Metal stamping machines can punch and bend metals into complicated shapes with a high degree of accuracy. The hardest part of the process is working with engineers to create the customized die needed for your product. Once the die has been created, the metal stamping process can be repeated and manufactured easily using highly technical and sophisticated stamping machines.

Common materials available include aluminum, brass, bronze, carbon steel, copper, stainless steel, steel, cold rolled steel, galvanized steel, high strength steel, hot rolled steel and tin plated steel.

Most thicknesses can be stamped. It depends on the tonnage of the press.

CNC machining. Bending, embossing, flattening, hand welding, in-line punching, mitering, notching, piercing, punching, tabbing, tapping, and minor assembly.

Depending on complexity of the stamping, a typical cost for a customized stamping dies can range from $2,500 to $50,000.

The lead time for metal stampings typically depends on the complexity of the stamping. However, in general a good time frame is between 8 – 20 weeks.

Typically, a good range annually is between 25,000 pieces to 250,000 pieces.

There is typically a set up charge with laser cutting and then the price is dependent on how long it takes to laser cut the part. If a CAD drawing can be supplied, sometimes the set up charge can be waived.

Laser cutting offers a high degree of precision, clean edges, short lead times, repeatable process for large volumes, and an automated manufacturing process.

Laser cutting can be used with a variety of metals. Some commonly used materials for laser cutting include aluminum, brass, stainless steel, and low-carbon steel. Environmental factors, decorative applications, durability, and longevity needs all play a factor into what type of material should be used.