Interested in talking to us about one of our products?

Call us at (770) 684-2481 or email at sales@zauderer.com

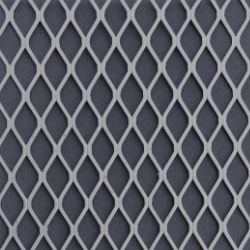

What is expanded metal? Expanded metal is an industry term that refers to metal that is cut by an industrial die and expanded (stretched), creating a diamond pattern. There are many industrial applications for this kind of material, which provides strength, flexibility, and various surface finishes, while being processed into coil and sheared sheets.

Manufacturers that produce air filters rely on expanded metal to give their filters strength with open area for ventilation. This makes expanded metal a key component in manufacturing air filters, including:

With so many types and variations of expanded metal intended for so many applications, how can manufacturers be sure they’re getting the right pattern and material for their air filter products? At Zauderer Associates, we’ve spent over four decades fielding questions from manufacturers just like you in pursuit of the right expanded metal for air filtration products.

Let’s take a look at the most frequently asked questions and the information you’ll need to consider when sourcing expanded metal.

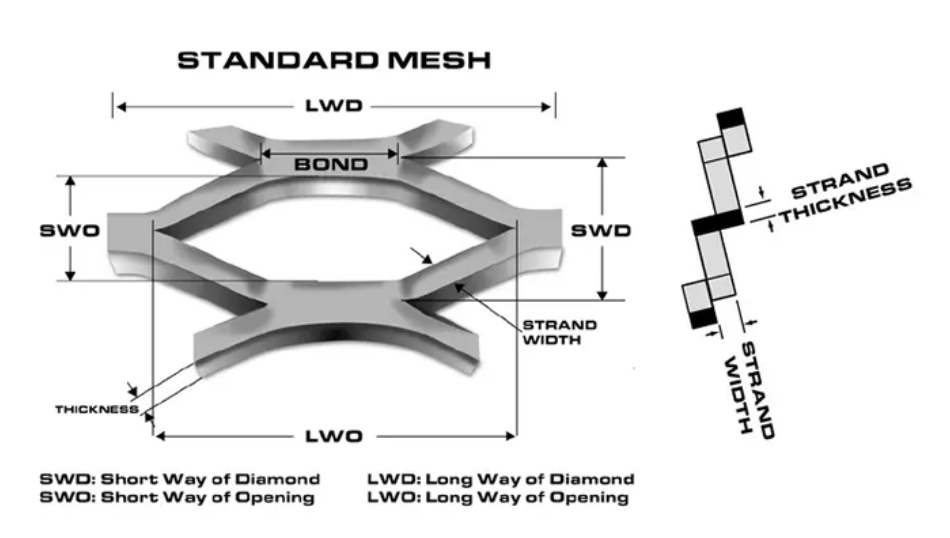

Determining the correct expanded metal pattern requires understanding the strength requirements, type of metal needed, and how much airflow is necessary. For example, the thicker the strand width, the stronger the expanded metal will be. The thickness of the expanded metal is usually determined by the column strength required in a specific application. Lastly, the larger the opening (open area), then the greater the airflow that is created.

Below is terminology that is helpful in determining the correct type of pattern for your project:

Once you have determined what pattern of expanded metal that you need for airflow and strength, then you will need to determine if you want coil or cut to size parts:

There are many standard sheet sizes available at distributors but if you want to purchase your expanded metal coil or sheets to your exact specification, you will need to buy from a manufacturer of expanded metal. Zauderer Associates sells customized patterns of expanded metal in coil and sheet to meet your specific requirements for airflow, environment, and strength.

Since air filters are finished products that require expanded metal in different thicknesses, materials and gauge sizes, due to their specific function, it’s important for filter producers to find an expanded metal manufacturer that can custom produce expanded metal at different sizes and thicknesses from .016” to 0.055” thick, depending on the material chosen.

Some filter producers will buy standard sheet sizes and cut them down themselves, but this creates a less efficient process and generates significant scrap. Look for a producer who can meet your exact expanded metal specifications for sheet sizes with widths from 2” all the way up to 48”.

Since expanded metal is made from one intact sheet of material, it is much stronger than other types of mesh like chicken wire, which is assembled from individual wires. When used in construction applications, expanded metal is favored because it can be customized with different angles and hole sizes to maximize strength.

For industrial air filtration manufacturing purposes, the key is to find an expanded metal product that is strong without compromising flexibility where required. Expanded metal manufacturers who specialize in serving air filtration producers can provide metal that is flattened or unflattened (louver effect) and in coil or cut to size sheets, depending on the needs of the customer.

On its own with no coating, CRS expanded metal will rust like any other steel product—but not all expanded metal is made the same. For filtration systems where moisture is a concern, it’s important to choose the right material that offers various coatings to protect the expanded metal from rusting. A list of common materials for expanded metal can be found below.

Expanded metal can be made from many materials, including:

When you’re looking to buy, not just any expanded metal, but the right expanded metal for air filtration products, it’s important to partner with a specialist who understands the specific considerations for manufacturing of this kind.

Since 1954, Zauderer Associates, Inc. has helped manufacturers simplify the purchasing process for the critical components they need to deliver a top quality finished product. We have represented the same expanded metal producer for over 40 years, and we leverage our expertise to make it easier for manufacturers to purchase the customized expanded metal products they need.

With strategically located representatives throughout the United States, we’re positioned to take the guesswork out of the buying process with straight answers to questions like these, rapid sample submissions, and fast turnaround times for expanded metal that meets your exacting specifications.

Still have questions? Need to fill an order quickly to keep your production moving? Contact Zauderer Associates, Inc. today.