Rivets and other cold formed parts are small-but-mighty components in many manufacturing operations. These fasteners secure and reinforce products across industries as diverse as automotive, cutlery, electrical manufacturing, sheet metal fabrications, furniture, and more.

Manufacturers need both high-quality rivets and high quality riveting machines for a perfect installation. In this blog we review frequently asked questions concerning rivets and the rivet machines that install these cold formed parts.

How to Select a Rivet Machine

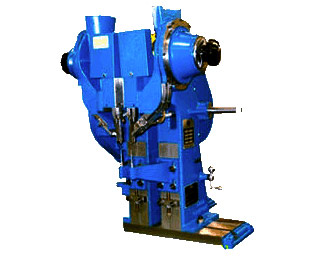

Choosing the right riveting machine depends on the materials that the machine will be joining together, as well as what type of tooling you will need when manufacturing your product. You must also determine if you need a machine that does impact riveting, orbital riveting, or a more specific type of riveting.

- Impact Riveting drives the rivet downwards through the materials into a forming tool known as a rollset. The rollset causes the rivet to flare out, often on the underside or interior of the product being manufactured. Impact riveters are very fast, achieving each rivet in less than a second.

- Orbital Riveting uses a spinning tool called a peen to press down into the rivet and spread it out into the desired fastening shape. These machines offer more control over the process, but it takes 2-3 seconds per rivet to get the job done.

- Radial Riveting is similar to orbital riveting, but the peen follows a more complicated path to expand the rivet in many directions at once. This is a slow process that allows even easily-fractured ceramic to be riveted with a high quality bond that does not compromise the surface structure.

Orbital riveters are generally the type of machine required for delicate applications like manufacturing electronics or in certain areas of automotive manufacturing. Knowing the type of rivet machine you need for a particular job is just the beginning. There are several different types of riveting machines for manufacturers to choose from:

- Motor-Driven Riveting Machines: Electrical motors can produce significantly more force than pneumatic motors; however, the amount of force is fixed. Though some motor-driven riveting machines come with speed settings, they may not be as adjustable as pneumatic machines. These rivet machines come in single, dual-head or multiple head models that can install one, two or multiple rivets at once, ranging in size from .03 inches to .6 inches in diameter and up to 3 inches in length.

- Pneumatic Riveting Machines: Pneumatic riveting machines will produce significantly less force and torque than an electrical motor-driven machine. However, the force can be more precision-tuned to accommodate different materials. These rivet machines also come in single, dual-head or multiple head models that can install one, two, or multiple rivets at once, ranging in size from .03 inches to .25 inches in diameter and up to 1 3/8 inches in length.

- Custom Riveting Machines: Custom riveting machines can be developed to meet the needs of each manufacturer, including machines with both motor-driven and pneumatic capabilities. We specialize in providing ready-to-run custom riveting machines that accommodate varying rivet diameter and length requirements.

Manual Riveting Tools: There are also hand tools that allow manufacturers to carry out riveting manually. Manual hand riveting tools work well for light assembly, low volume production, repair, and maintenance that involves various sizes of semi-tubular rivets.

Where to Purchase a Riveting Machine

Now that you have perspective on the various types of rivet machines and which might meet your needs, the question arises of where to purchase the riveting machine. We believe it’s important to purchase your rivet machine from a manufacturer that also performs in-house repairs and rebuilding. This allows for you to work with one provider over the lifetime of the machine, and you know the manufacturer will have easy access to any rivet machine repair parts that need replacement. Additionally, the manufacturer should offer troubleshooting and technical support to help you address any issues on-site. Our riveting machines are proudly made in the USA and all repairs, customer service, and technical support are carried out in the same location.

How to Design a Proper Rivet

Proper design of a rivet involves the diameter, length, and material the rivet is created from. The diameter and length determine if the rivet will keep the joint strong over time as shear and tensile strength is tested. Creating the rivet out of material that is compatible with the materials to be joined is essential to prevent corrosion. In use cases like automotive manufacturing, aerospace manufacturing, or electronics manufacturing, the specific industry may have distinct rivet design and quality requirements that are partially determined by regulation.

We can custom create rivets according to the design specifications below, and using the following materials and finishes:

- Rivet Diameter: Ranging from .03 in/.762 mm to .562 in/ 14.275 mm

- Rivet Length: Maximum of 5 in/127 mm

- Rivet Materials: Aluminum, Brass, Carbon Steel, Copper, Stainless Steel, and Alloys

- Rivet Finishes: Anodizing, Black Oxide, Brass Plating, Copper Plating, Galvanized, Gold Plating, Nickel, Painted/Japanning, Silver Plating, Zinc

Different Types of Cold Formed Rivets and Rivet Heads

Because we serve a wide range of industries, each with distinct requirements, we pride ourselves on the breadth of our manufacturing capabilities for all cold formed parts and cold headed fasteners we produce. These include:

- Collar Rivet

- Complex Geometry

- Cutlery Compression

- Electrical Contacts

- Fluted Rivet

- Knurled Rivet

- Rivet Caps

- Self-Piercing Rivet

- Shoulder

- Square Shank

- Split

- Solid Rivet

- Semi-Tubular Rivet

- Fully-Tubular Rivet

Depending on the application of the rivet and the machinery being used to install the rivet, we also have a variety of different rivet heads available, including:

- Button Head

- Countersunk Head

- Decorative Head

- Flat Head

- Flat Countersunk Head

- Oval Head

- Slotted Head

- 6 Lobe

Working with a Cold Formed Parts Manufacturer

We use a cold heading process to create all the custom rivets provided to manufacturers. Cold heading is a process that reduces materials scrap and allows for high-speed, consistent production that means we can meet rush orders without compromising on quality. We are proud that the cost benefits achieved through the efficient cold heading production process are passed down to our customers. This includes cost savings on intricate designs that might otherwise be more expensive to produce through other manufacturing methods. As new innovations become available we constantly reinvest in our processes to bring customers the best possible products through cutting-edge technologies.

We hope this list of FAQs has given you some insights into rivet machines and sourcing custom rivets and fasteners for your manufacturing operations. If you still have more questions about your facility’s needs or whether we have the capability to fill your order quickly, reach out to Zauderer Associates today.