Interested in talking to us about one of our products?

Call us at (770) 684-2481 or email at sales@zauderer.com

Furniture manufacturers know that comfort and long-lasting quality are essential to the reputation and success of their product lines. The choice of upholstery coil is the biggest influencer of product comfort and also plays a major role in the lifespan.

Explore these FAQs to guide you as you choose furniture springs.

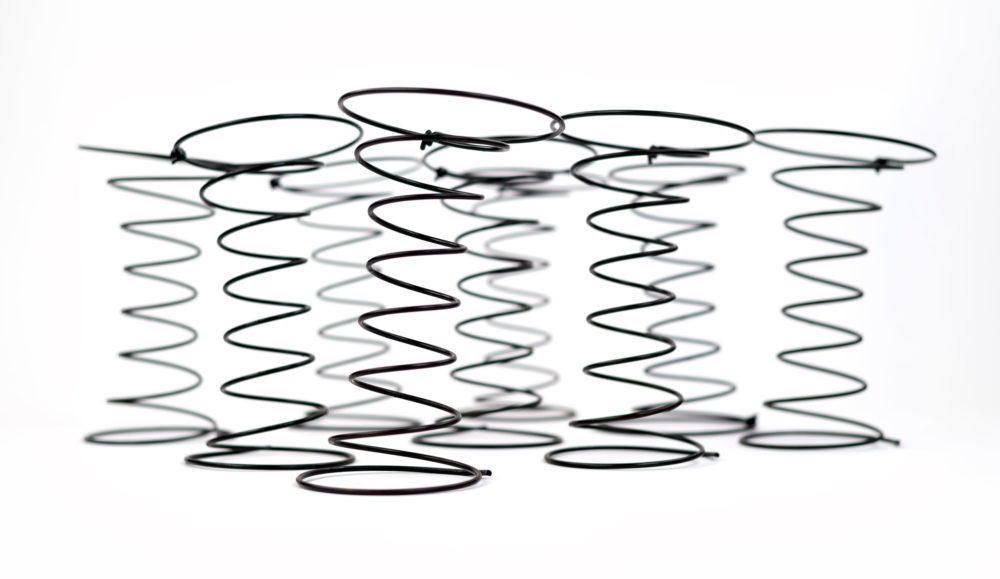

One of the easiest ways to upgrade the ride of your furniture is using better-quality furniture springs, including drop-in units, upholstery coils, Marshall units, and sinuous springs. The size and gauge of each can be adjusted to fit each custom furniture design, including not only the dimensions of the product but also the desired level of firmness or softness.

Upholstery springs support the seats and backs of furniture such as sofas, loveseats, chaises, chairs, etc. Springs are typically found in the body of the seat, underneath the padded cushion, as well as in the backs. There are two main types of springs used in upholstered furniture: coil springs and zig zag or sinuous springs.

In high quality furniture, there are two types of coil spring foundations: 8-way hand tied and drop-in units.

Many manufacturers and consumers alike wonder what is the best alternative to 8-way hand tied. As the name implies, 8-way hand tied foundations must be hand-crafted by a skilled professional who hand ties each spring at eight different points and attaches each spring to the furniture frame. This web of twine allows each individual coil to work with the other coils as a system and preserves the quality of the furniture over time. However, this is also a very expensive and time-consuming process for creating furniture.

Today, one quality alternative to 8-way hand tied furniture is a piece of furniture built with a drop-in construction. Single-cone coils are securely clinched to roll-formed steel channel bars, creating the rigid bar drop-in construction unit. The frame becomes stronger when the bars of the unit are screwed into place. This type of unit can be custom designed to fit any type of furniture frame in either full size (one piece) or modular units. Rigid bar drop-in construction offers support similar to an 8-way hand tied foundation with less labor costs and without the need of a skilled 8-way hand tied craftsman, since these units simply screw into the frame. Among drop-in units, our rigid bar drop-in unit is the best in the industry.

In our drop-in unit, individual coil springs are connected through link-top fabrication to spread the weight load more evenly than in an 8-way hand tie base. The wire gauge, coil height, number of turns in the coil, and location of the springs on the bar can be custom engineered to accommodate every need. Once installed, the drop-in unit strengthens the customer’s frame, allowing them to remove wood slats or bracing. Modular units allow chairs, loveseats, and sofas to be manufactured using the same unit (one unit for a chair, two units for a loveseat and three for a sofa). This means customers can cut down on SKUs, plus eliminate freight and handling issues that can happen with larger one-piece sofa drop-ins.

A Marshall spring cushion unit is a highly adaptable product that can be used in either the back or the seat of a piece of furniture. Coil springs made from high-carbon wire are specially formed to meet the demands of each unit manufactured. Springs are pre-tensioned to the correct height, allowing for years of durability and comfort. Coils are then encased in durable material and either scrim-glued or hog-rung to create the desired comfort and ride. For manufacturers who need to employ a custom use, Marshall coils can also be purchased as continual coils of individual springs.

Whether a sofa, chair, loveseat, or other piece of furniture that will find its way into a home, superior spring quality makes these products into investments that customers will value and recommend to others.

We hope this list of FAQs has given you some insights into choosing furniture springs for your manufacturing operations. If you still have more questions about your facility’s needs or whether we have the hardware in inventory to fill your upholstery coil order quickly, reach out to Zauderer Associates today.