Interested in talking to us about one of our products?

Call us at (770) 684-2481 or email at sales@zauderer.com

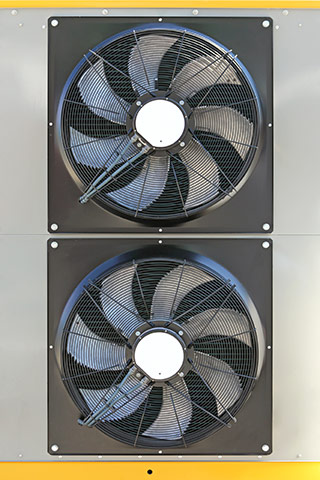

An axial fan causes air to flow through it in an axial or parallel direction to the shaft where the fan blades are attached. Axial fans are used to move heated or cooled air or for ventilation applications. The axial fan is the oldest design of a fan. The early use of axial fans can be seen in windmills made of wood from man’s earliest times.

An axial fan causes air to flow through it in an axial or parallel direction to the shaft where the fan blades are attached. Axial fans are used to move heated or cooled air or for ventilation applications. The axial fan is the oldest design of a fan. The early use of axial fans can be seen in windmills made of wood from man’s earliest times.

The blades used on axial fans can be from very small sizes up to large diameters like used on wind turbines. The simplest axial fans have the blades made in one piece in many different materials which are attached to motors to turn the blades. These fans have the blades tipped or pitched to push the air and are relatively inexpensive. Larger axial fans have blades that are added to a hub which is attached to motor shafts. The larger industrial axial fans have the blades attached to hubs, by rivets or welding, with the hubs then mounted on drive motors to turn the fans. The pitches of the blades can range from fixed to adjustable.

Refinements in fan design have produced more efficient and economical fan blades which move more air and use less power. Axial Fan motors have also been refined. The motors can adjust the speed of the axial fans as well as provide feedback on the performance of the fan. Axial fans are used in a multitude of sectors including HVAC, ventilation, automotive and aircraft to name a few.

Axial Fans are designed to specific operating points. An operating point consists of the amount of air produced (CFM, liters/sec.) at a static pressure (in/HG, Pascals). The axial fan is normally used to move a lot of air but at a lower static pressure. Centrifugal fans move less air but at higher static pressures. Axial Fan performance curves are developed for the fan which shows the performance changes if the CFM or static pressure are changed. Fans are designed to operate at specific speeds and wing tip velocity comes into play using the larger diameter wind turbines. Axial Fans have areas of the performance curve where they cannot operate and will stall.

Motorized axial fans have been around for a long time and these have the fan blades mounted on AC motors which turn the fans. Recent changes have resulted into motorized external motor rotors. These fans have the fan blades attached to the outside of the motor housing which spins. In both cases due to the rotation of the fan it can develop an out of balance or wobble which can lead to failure of the fan. Most fans used are balanced during manufacturing, by static or dynamic balancing, which trues up the fan to operate up to its maximum speed without wobble. Tube axial fans can be used up to very high speeds and exhaust fans are used in many everyday places like kitchens and bathrooms, livestock barns, industrial applications, etc.

For more information on the types of air moving components that we sell, please click here.

If you have any specific questions on EC Motors or AC, DC and EC fans, please read “EC Motor and EC Fans.”

We can supply motorized axial fans using external rotor motors in AC, DC and EC versions. Please click the “Request More Info” button below if you need help determining the right axial fan for your needs.