Interested in talking to us about one of our products?

Call us at (770) 684-2481 or email at sales@zauderer.com

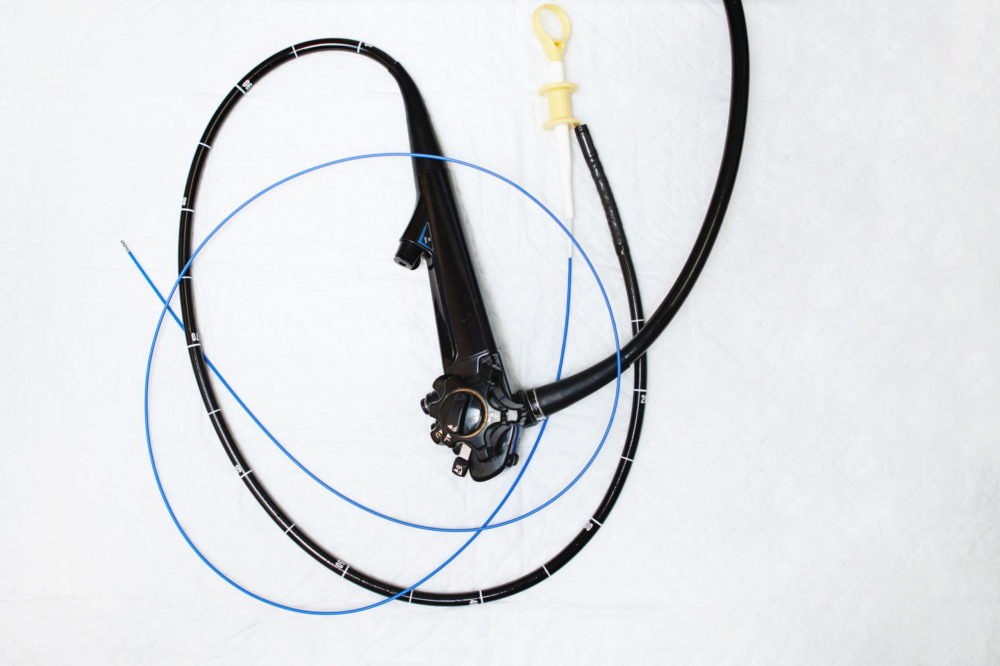

Wire rope cables and cable assemblies are relied on by our customers across a wide range of industries and product lines. With almost 50 years of manufacturing and engineering experience, we support clients around the world every day with high-quality wire rope cable. These cables are used in a range of simple to complex applications in medical devices, industrial manufacturing, aerospace engineering, consumer products, and beyond. Let’s explore commonly asked questions about finding the best wire rope cable for use in your manufacturing operations.

Wire rope cables and cable assemblies are a diverse range of products that meet many different demands across consumer and non-consumer markets.

These are just some of the uses of wire rope cable that we help clients and manufacturers achieve. From initial concept to the product run, our principal’s engineering team is experienced at helping organizations achieve their vision while also remaining compliant with unique industry regulations and exceeding end-user quality expectations.

Here is a list of the different materials that a wire rope cable can be made from:

In addition, wire rope cables may be coated with some of the following materials:

Depending on the standards and regulations in your industry, different wire rope cable materials and coatings may be required, or prohibited, by law.

Steel is generally considered the strongest wire rope cable material. However, strong cables can be fabricated of any material depending on the custom requirements of a client’s need. Decades of engineering and manufacturing experience make us a trusted provider of custom wire rope cable solutions that serve any situation.

Each diameter of wire rope cable comes with different maximum load bearing capabilities. We can produce wire rope cables relevant to exact needs concerning the breaking point, cable diameter, cable materials, cable grade, or cable construction specifications.

Both fiber core ropes and wire strand core ropes can be engineered and manufactured to provide the required flexibility of your project. Flexibility is determined by both the number of wires in each strand, and the number of strands that make up the rope. For instance, a 7×7 construction would mean there are 7 strands in the rope, and 7 metal wires that make up each strand. This means a total of 49 wires make up the rope. Wire rope cable becomes more flexible as the number of strands increase within a particular diameter. Therefore, while a 7×7 wire rope cable is thought of as a flexible rope, 7×19 construction is even more flexible. This wire rope would be made up of 7 strands, with 19 wires per strand for a combined total of 133 individual wires. 7X19 wire rope cable is often used in pulley systems where flexibility is required.

The success of products using wire rope cable also depends on the quality of associated cable assemblies and fittings. Custom-designed wire assemblies and fittings must be engineered to last, and consistency is essential so that the hundredth or thousandth fitting that is used is the same as the first. Here are some of the wire rope end fittings, cable pulley fittings, and other unique fittings for custom applications that we can provide:

Additionally, we also produce a series of different kinds of pulleys, including bearing-mounted pulleys, custom timing pulleys, nylon pulleys, high-endurance pulleys, cable/cord idler pulleys, and other push/pull components and terminals that are essential to the design of a custom pulley system or custom wire rope assembly. We not only can provide the hardware to create the system, but also consult on the design that will help achieve the task at hand with a cost-efficient and long-lasting solution that end users will appreciate.

Our principal is not only an ISO 9001:2015-compliant expert but also is RoHS and REACH compliant. They also maintain FDA Registered Status and ITAR Registered Status. Decades of engineering and manufacturing experience is paired with a commitment to stay educated on the changing standards of compliance and quality that allow excellent products to be delivered to manufacturers across the world and used with confidence.

We hope this list of FAQs has given you some insights into sourcing wire rope cables, pulleys, and wire fittings for your manufacturing operations. If you still have more questions about your facility’s needs or whether we have the capability to fill your order quickly, reach out to Zauderer Associates today.